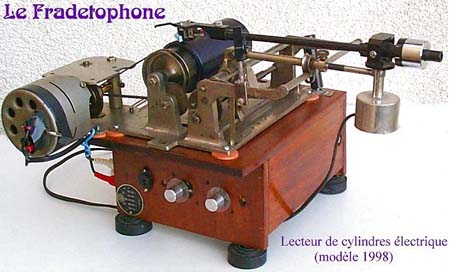

Electrical playback of cylinders

Since the early days, sound recording has been far superior to sound reproduction. Early apparatus could reproduce only a fraction of the frequencies recorded on the cylinders (from 300 to 3000 Hz with the best ones). Acoustical reproduction systems were so limited in the higher and lower end of the spectrum that they could not even reproduce a female voice correctly - not to mention piano music. Only electrical playback allows us to hear all that has been recorded on a cylinder, and we are often surprised. All cylinders are "hill and dale" vertically cut, like Diamond discs . So we will use a Shure SC35C cartridge wired for vertical response.

Which phonograph to use

For playing old discs we can use a modern turntable with an electric motor, but unfortunately there is no cylinder player equipped with an

electric motor. The first solution would be to build a machine specifically for this use: it is possible, but it is a matter of precision

mechanics and high skill in that field is required. Just take a look at the work of a few especially talented amateurs on an extraordinary site

dedicated exclusively to modern cylinder phonographs You can find inspiration there if you feel you are capable of getting into such a project. The other solution, the one I have adopted, is to use the works of an old phonograph. For the purist, it is a less satisfactory solution, but it has the advantage of being feasible by a moderately skilled amateur, and for a very modest price too. This is the interest of the "Fradetophone" (unregistered trade mark !)described here.

A bare mechanism without the wood case can still be found easily and cheaply, and with a bit of work it can serve as a base for our electrical

player. But do make sure it is a model equipped with a feedscrew that permits the reproducer to track the groove. So you can exclude the

Pathé O and Puck types, whose mechanism is too weak anyway for serious use. Another must is that the mandrel be of the standard type, which allows for standard cylinders and Salon (Intermediate Pathé) cylinders with an adaptor. The Pathé Chanteclair will only take Salon cylinders and the Phénix will only take Phénix cylinders (practically impossible to find and with a very special diameter). The Edisons will only take standard

cylinders and do not allow for the use of an adaptor. The ideal is to find a Pathé No 1 (a fairly common model) which has a pretty

robust mechanism, with a feedscrew and which takes the two common diameters of cylinders. Of course, the large Concert cylinders will not be playable on it, but as there is a very slight chance for you to have any, I just skipped the question.

Mechanical or electrical motor?

The easy solution is to keep the original mechanical motor... if it works

- provided it is not too noisy. Most small models actually produce a

terrible noise which is picked up by the cartridge - and amplified! This

mechanical noise somtimes spreads over the entire useful spectrum of

frequencies and will thus be impossible to eliminate. If the original

mechanism does not work, so much the better. Just take it out (but don’t

throw it away, there may be parts there to recover to repair a

collector’s phonograph). A good starting point is to find a quiet

electric motor, which is a lot more convenient. I personally use a DUAL Pick-up

motor for 78’s of the 1930’s. Those can still be found easily at flea

markets for a modest price. They are very interesting, for they

are strong, fairly quiet and above all they have a centrifugal three-weight governor

that allows for perfect speed control. We will only remove the

turntable spindle and use the helical gear (after

soldering a brass sleeve onto it) as the primary pulley. Make a

leather belt to connect this pulley to the mandrel pulley. Then put your

ingenuity to work and mount the motor giving it some clearance so you can

adjust the tension of the belt. I recommend you to spray

the inside of the belt with a special compound that will help avoid slippage

and power loss. At last check if the mandrel is heavy enough to work

as a flywheel that will absorb small speed variations . If it is not so,

then open it. It is hollow and the lid can be easily removed. Melt some lead

(or tin solder) into it to obtain a thick and even layer, without of course obstructing

the hole for the central axle. The mass of lead should be perfectly

balanced in order to function as a flywheel.

.

How to fix the electrical pick-up arm

The Pathé No 1 phonographs are provided with the"Orpheus" system, which

means the reproducer and horn move together along the cylinder. The

reproducer should have some vertical and lateral mobility while always

staying level.

We will keep this excellent "Orpheus" system and

simply replace the reproducer-horn unit by a modern arm fitted with a

magnetic cartridge. So we must take a complete arm with its pivot and

counterweight from a modern turntable. The problem will be to find a

straight arm (not an S-shaped one) and fix it on the antique cylinder

phonograph. The image above shows the system I use, but it can

certainly be improved on. The counterweight permits adjustment of

pressure according to the cylinder to be played. Normally 3 grams will

be quite enough except if the cylinder is a little excentric, in which

case you may increase pressure to 5 grams to keep the stylus from taking

off at every revolution.

Which stylus to use

The original "sapphires" were in most cases small glass balls. If you have an original one, you may try and glue it to a used microgroove stylus bar. You will need a watch-maker’s magnifying glass, a pair of very fine tweezers, some cyanolite glue - and the patience of an angel. But it can be done. A Shure cartridge fitted with such a ”sapphire” will perform well, especially with brown wax cylinders. In difficult cases, with cracked or badly worn cylinders, only the glass ball will be able to jump over the cracks and keep tracking the groove. But for black cylinders, which are made of a much harder material, the glass ball should not be used. It is more advisable to use a practically everlasting diamond stylus, which will reproduce more treble. The English manufacturer Expert Stylus makes 7 mil diamond styli for Shure cartridges, especially intended for use with standard 2 minute cylinders.

Adjusting the speed

Cylinders normally spin at 160 rpm. This is the rule for black moulded cylinders. Brown cylinders do not always respect this speed and many of them run at slower and very different speeds. There is no other option than to set the speed by ear. All mechanical phonographs have a speed adjustment that allows us a wide range of speeds. We are now going to attach a stroboscope for 160 rpm to the end of the mandrel and stick with that speed in most cases. If the sound seems unlikely at that speed, reduce speed until it sounds right. Most certainly very subjective, but there is no other way...

Electrical connections

The signal produced by the cartridge is very weak and very susceptible

to intereference. Therefore good shielded cables are essential. Some

"shielded" cables for HiFi are real sieves and so practically useless.

Choose only cables with a densely woven braid that surrounds the

central conductor completely. This is the only way to avoid undesired

hiss, hum and crackle. Connect the two RCA plugs into the phono input

of your amplifier, the only input that can be used with this kind of

reproducer. Even so we must know one important thing: all phono inputs

on all contemporary amplifiers include a filter called RIAA, which

raises the low frequencies and lower the high, correcting the frequency

curve of the microgroove discs. Older phonograms (discs and cylinders)

have not been recorded according to this curve. We must then use a

special preamplifier or a graphic equaliser to cancel this RIAA

correction. Anyway, when playing cylinders, electric reproduction will

give a terrible mechanical noise in the low register, and at the high

end a no less terrible surface noise. It is absolutely necessary to

filter out all useless frequencies and keep only the useful signal. On a

cylinder there is nothing below 300 Hz neither above 4000 Hz, so you can

filter drastically without regrets. Then what you have is the signal in

all its - relative - clarity. And if you have no filters or equaliser,

set the bass and treble to minimum. It is better than nothing and it

permits listening to your old cylinders in relative comfort.

But in order to make

high quality transfer of cylinders, this is very insufficient, and

in that field, computerised sound processing is a must. That will

be the subject of the following chapter